Sectional Water Tank Installation Requirements

Sectional Tank Installation Guidelines

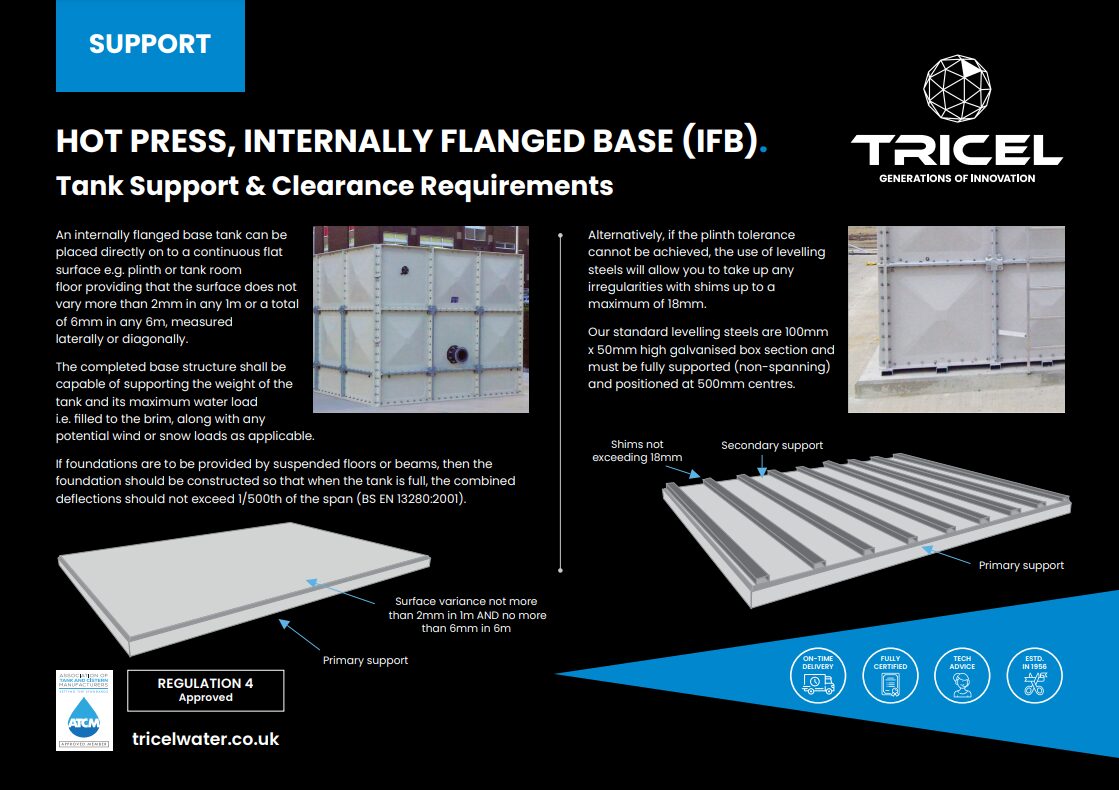

The tank type determines the type of foundation that may be used for installation. Base guidelines are provided for each sectional tank ordered.

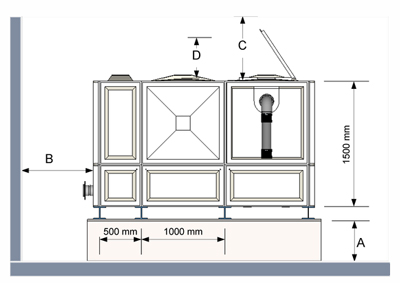

Externally Flanged Base (EFB) Sectional Tanks

Option 1 – Solid bearers

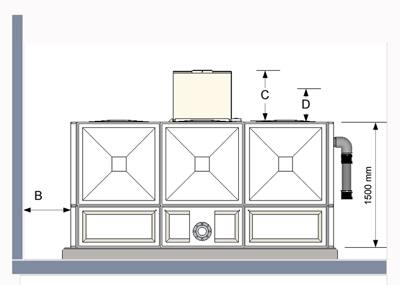

Concrete dwarf walls – placed at 1000mm centres for metric tank panels. As space is required underneath the tank, externally flanged base tanks must be placed on an elevated structures outlined in the image.

Option 2. Steel supports

Parallel steels beams placed on raised steel supports. Steels placed at 1000mm centres metric tank panels.

Option 3. Secondary Steels

Concrete dwarf walls with parallel steels running perpendicular to dwarf walls. Primary walls centres no less than 750mm. Steels placed at 1000mm/500mm centres metric tank panels. This arrangement becomes necessary where access is restricted due to primary supports at 500mm centres.

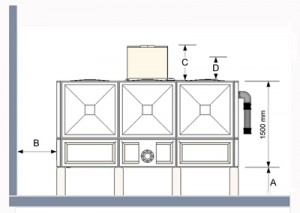

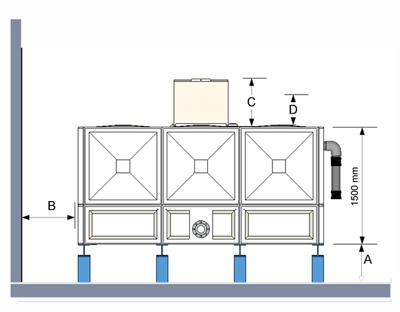

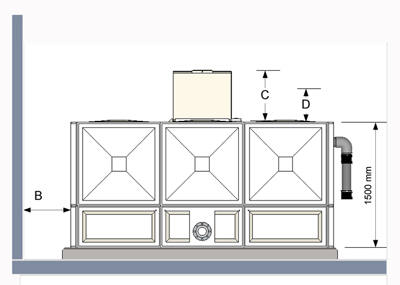

Sectional Tank Support and Clearance Requirements

Space Requirements for Sectional Tank Installation

| A | B | C | D | |

| Tanks up to 3m deep | 600 | 425 | 750 | 500 |

| Tanks 2m – 2.5m deep | 600 | 525 | 750 | 500 |

| Tanks 3m – 4m deep | 600 | 625 | 750 | 500 |

Clearance dimensions in mm

Clearance may be varied by agreement for small tanks where access is deemed suitable.

Ladders with hoops will require a space of at least 1030mm.

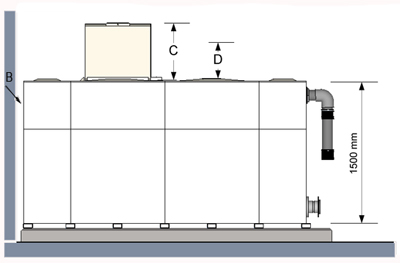

Sectional Tank Base Requirements

Option 1 Concrete plinth

Flat concrete plinth- ensuring the plinth is level and that it extends 150mm beyond the tank internal length and width dimensions

Option 2 Steel supports

Parallel steel beams – placed at 500mm centres metric tank panels.

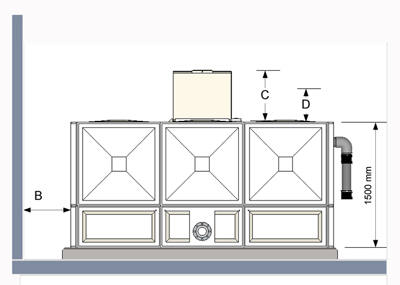

| Internally flanged base tanks | B | C | D |

|---|---|---|---|

| Tanks up to 3m deep | 425 | 750 | 500 |

| Tanks 2m – 2.5m deep | 525 | 750 | 500 |

| Tanks 3m – 4m deep | 625 | 750 | 500 |

| Clearance dimensions in mm. Clearance may be varied by agreement for small tanks where access is deemed suitable. Ladders with hoops will require a space of at least 1030mm |

|||

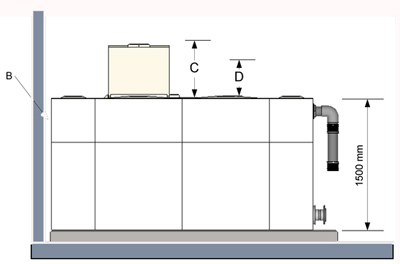

| Internally flanged (IF) tanks | B | C | D |

|---|---|---|---|

| Tanks up to 3m deep | 150 | 750 | 500 |

| Tanks 2m – 2.5m deep | 150 | 750 | 500 |

| Tanks 3m – 4m deep | 150 | 750 | 500 |

| Clearance dimensions in mm. Clearance may be varied by agreement for small tanks where access is deemed suitable. Ladders with hoops will require a space of at least 1030mm |

|||

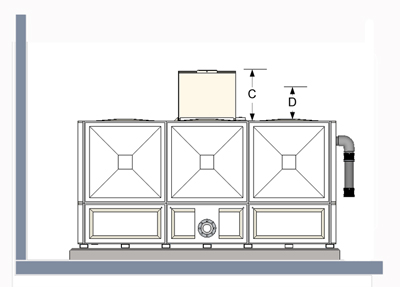

| Totally internally flanged (TIF) tanks | B | C | D |

|---|---|---|---|

| Tanks up to 3m deep | 50 | 750 | 500 |

| Tanks 2m – 2.5m deep | 50 | 750 | 500 |

| Tanks 3m – 4m deep | 50 | 750 | 500 |

| Clearance dimensions in mm. Clearance may be varied by agreement for small tanks where access is deemed suitable. Ladders with hoops will require a space of at least 1030mm |

|||

Why work with us for your Water Storage Needs?

Over 50 years’ industry experience

Projects completed in the last 24 months

Tricel Lanark is a UK GRP Cold Water Storage Tank Manufacturer with a proven track record in the supply of water tanks to all industry sectors throughout the UK. We have an expert team on hand with over 50 Years' industry experience. Our team works hard to provide exceptional industry lead times from quotes, site visits, order processing, and delivery. We are a British Standard approved company with full certification through BSI/ISO9001 including WRAS approved certified water tanks suitable for potable drinking water.

- Over 50 years of technical knowledge.

- Quality assurance at a local level.

- UK customer support teams, backup, replacement service & advice.

- Supporting local and sustaining UK manufacturing.

- Regional sales representatives for site visits, emergency water requirements, and project advice.

Data Centres

Airports

Government Buildings

Hotels

Our Accreditations

At Nicholson’s, we pride ourselves in manufacturing and installing GRP water tanks of the highest quality throughout the UK. Click to see Our Certifications.